Threading Die

Threading Die Specification

- Machine Type

- Die Stock, Hand Tool or Power Tool

- Features

- Uniform threading, durable, rust resistant, suitable for rethreading

- Operate Method

- Manual

- Tool Type

- Threading Die

- Cutting Speed

- 25-30 m/min

- Cutter Type

- Circular Thread Cutter

- Cutting Capacity

- Up to M24 threads

- Length

- 8mm-20mm (depending on size)

- Cutting Force

- Low

- Material

- High Speed Steel (HSS)

- Hardness

- HRC 60-65

- Operation Type

- External Thread Cutting

- Shape

- Round

- Cutting Accuracy

- High precision

- Coating

- Uncoated

- Diameter

- 25mm-50mm

- Maximum Torque

- 120 Nm

- Processing Type

- Thread Cutting

- Application

- Threading pipes, rods, and bolts

- Heat Treatment

- Fully Hardened and Tempered

- Blade Size

- Customizable, standard sizes available

- Surface Finish

- Ground

- Packaging Type

- Individual Box

- Suitable Material

- Mild Steel, Carbon Steel, Alloy Steel, Non-ferrous metals

- Reusability

- Reusable multiple times

- Product Life

- Long Service Life

- Standard

- DIN 223, ISO

- Thread Pitch

- 0.5mm to 2.5mm

Threading Die Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 1-7 Days

About Threading Die

Adjustable Round Split dies use a set screw for adjustment of the thread size for precision threading aplications.

High Speed Steel dies recommended for longer tool life.

The quality of our dies cuts excellent threads (even into stainless steel) and provides an acceptable alternative to HSS They are far superior to alternative carbon steel dies.

These dies offer significant savings to the model engineer over HSS while offering no sacrifice in quality and performance.

BSF

UNF

UNC

UNEF

UN

Whit Worth Fine

BSP

Metric Coarse and Fine

ME

BSC

BSCON

NPT

BSPT

PG

ACME

Precision Threading with Ground Finish

Our threading dies deliver uniform and accurate threading, thanks to high-quality HSS construction and ground surface finish. With high hardness (HRC 6065), they ensure smooth cuts and extend the products lifespan, even with frequent reuse.

Versatile Applications and Custom Sizing

Designed to accommodate thread pitches from 0.5mm to 2.5mm, these dies are suitable for a variety of threading tasks. Whether working with rods, pipes, or bolts, you can choose from standard sizes or request customized blades to meet unique engineering needs.

Reliable Performance and Longevity

Each threading die undergoes full hardening and tempering, contributing to long service life and consistent performance. The uncoated, rust-resistant design makes them ideal for demanding operations and supports fast cutting speeds for efficient threading.

FAQs of Threading Die:

Q: How do I use a threading die for external thread cutting?

A: To use the threading die, secure it in a die stock tool and manually rotate it over the pipe, rod, or bolt requiring threads. Ensure the material matches suitable types (mild steel, carbon steel, alloy steel, or non-ferrous metals) for optimal results.Q: What thread sizes and pitches are supported by this die?

A: Threading dies are available for pitches ranging from 0.5mm to 2.5mm and can cut threads up to M24. Blade sizes and die diameters (25mm to 50mm) can be selected according to your threading requirements.Q: What benefits does full heat treatment offer for this threading die?

A: Full hardening and tempering provide increased durability, superior cutting performance, and extended product life. This process ensures the die maintains its shape and precision even with repeated usage on tough materials.Q: Can the threading die be used for rethreading worn or damaged threads?

A: Yes, the die is ideal for rethreading worn or previously damaged bolts, rods, or pipes, thanks to its high precision and robust design. The uniformly ground blades help restore threads with excellent accuracy.Q: Where is this threading die commonly distributed and supplied?

A: This threading die is widely distributed, exported, imported, supplied, and traded in India through various channels including distributors, wholesalers, and traders.Q: Is the threading die reusable and how many times can it be used?

A: The die is designed for multiple uses, backed by its fully hardened and tempered structure and rust-resistant finish. Its longevity depends on material hardness and cutting frequency, but it generally offers a long service life.Q: What are the main advantages of choosing a threading die with a ground surface finish and high-speed steel material?

A: A ground surface finish ensures consistently accurate cuts and minimizes friction, while high-speed steel offers excellent wear resistance, rust protection, and the ability to maintain performance under high cutting speeds and torque.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Cutting Tools Category

End Mill

Price 553 INR

Minimum Order Quantity : 1 Piece

Features : High Precision, Durable, Corrosion Resistant, Smooth Chip Removal

Tool Type : End Mill Cutter

Cutter Type : Flat, Ball Nose, Corner Radius

Material : Others, High Speed Steel (HSS) or Solid Carbide

Carbide Insert Tap - Threading

Price 453 INR

Minimum Order Quantity : 1 Set

Features : Wear Resistant, Long Service Life, High Surface Finish

Tool Type : Insert Tap

Cutter Type : Threading Cutter

Material : Tungsten Carbide

HSS Spiral Fluted Tap

Price 1053 INR

Minimum Order Quantity : 1 Set

Features : Efficient chip removal, Suitable for blind holes, High precision

Tool Type : Thread Tap

Cutter Type : Spiral Flute Tap

Material : Others, High Speed Steel (HSS)

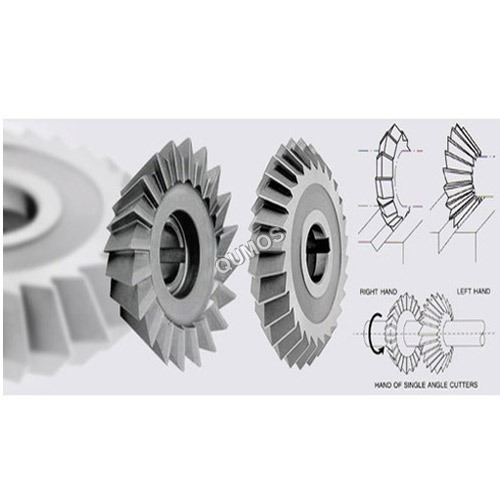

Angle Cutter HSS

Price 1053 INR

Minimum Order Quantity : 1 Piece

Features : High durability, precise cutting, corrosion resistance

Tool Type : Angle Cutter

Cutter Type : Angle Cutter/HSS Side & Face Cutter

Material : Others, High Speed Steel (HSS)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry