Angle Cutter HSS

Angle Cutter HSS Specification

- Operate Method

- Manual or Machine Operated

- Tool Type

- Angle Cutter

- Cutting Capacity

- Varies by diameter

- Shape

- Angle

- Cutting Accuracy

- 0.05 mm

- Features

- High durability, precise cutting, corrosion resistance

- Operation Type

- Slotting, Milling

- Coating

- Uncoated

- Cutter Type

- Angle Cutter/HSS Side & Face Cutter

- Hardness

- 58-60 HRC

- Length

- Available in several lengths (typically 50100 mm)

- Machine Type

- Milling Machines

- Cutting Speed

- High

- Cutting Force

- Optimized for efficiency

- Material

- High Speed Steel (HSS)

- Diameter

- 50 mm (standard); customizable

- Maximum Torque

- Depends on application

- Processing Type

- Precision machining

About Angle Cutter HSS

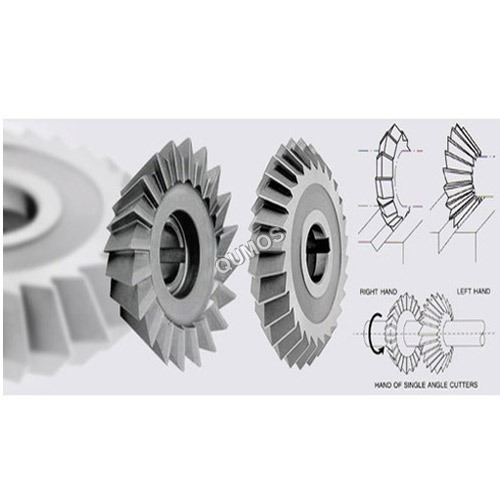

Angle Cutters (Single Angle Cutters and Double or Equal Angle Cutters) are milling cutters with their cutting face angled with respect to the axis of rotation. There are two types of angle cutters that we manufacture and stock which are the Single Angle Cutters and Double (Equal) Angle Cutters.

Single Angle Cutters are those which have teeth on the conical or angular face of the cutter and also on the large flat side. Double or Equal Angle Cutterd have V- shaped (equal angled) teeth with both conical surfaces at an angle to their end faces. Single Angle and Double (Equal) Angle Cutters are cutting tools commonly used for cutting various kinds of metals.

Single Angle Cutter Used for milling Dovetails, Serrations, Angular Slots or Chamfers. Note: A 1mm flat may be added to maintain integrity of the cutting point on certain angle and diameter combinations.

Double / Equal Angle Cutter Used for milling V-shaped slotts, serrations and chamfers. Note: A 1mm flat may be added to maintain integrity of the cutting point on certain angle and diameter combinations.

Precision Cutting for Diverse Applications

This Angle Cutter HSS excels in cutting slots, grooves, and precise angles in a wide range of metal materials. Its high level of hardness (58-60 HRC) ensures durability, while the fine or coarse teeth options allow users to tailor the cutters performance for different machining needs. The tools design is optimized for both efficiency and reliability in demanding metalworking environments.

Customizable Design to Match Every Need

Available in standard 50 mm diameter or customized to your specifications, this cutter can be tailored for various metal cutting tasks. With options for length (50100 mm) and blade size, it provides flexibility in application, making it a valuable asset for machinists and fabricators who require precise and efficient workflow.

Engineered for High Performance and Longevity

Manufactured from high-speed steel, the Angle Cutter HSS ensures exceptional durability and corrosion resistance, even under heavy industrial use. Its polished finish and uncoated surface maximize cutting efficiency, while the optimized force and torque ensure high productivity and minimal tool wear over time.

FAQs of Angle Cutter HSS:

Q: How do I choose between fine and coarse teeth configurations for the Angle Cutter HSS?

A: The selection depends on your desired finish and material type. Fine teeth provide smoother finishes and are ideal for harder or more delicate materials, while coarse teeth are better suited for faster cutting in softer metals or larger material removal.Q: What metals can the Angle Cutter HSS cut effectively?

A: This cutter is designed for use on various metals, including carbon steel, alloy steel, stainless steel, and cast iron, making it highly versatile for different machining tasks.Q: When should I use a customized blade size or diameter?

A: Customized blade sizes or diameters are recommended when your application requires slots, grooves, or angles that do not fit standard dimensions. Customization ensures optimal compatibility and efficiency for specialized jobs.Q: Where can the Angle Cutter HSS be mounted and operated?

A: The cutter features an arbor-mounted shank type and is suitable for use on milling machines. It can be operated manually or with machinery, depending on the application and user preference.Q: What is the recommended usage process for optimal performance?

A: Ensure the cutter is securely mounted and choose cutting speeds appropriate for the material being processed. Regularly check for wear and use coolant if needed to maintain blade life and accuracy during operation.Q: What benefits does the Angle Cutter HSS offer over other types of milling cutters?

A: Its high-speed steel construction delivers superior hardness and longer service life, while precision machining and customizable options offer accurate and efficient cutting for various industrial needs. High durability and corrosion resistance make it a cost-effective choice.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Cutting Tools Category

HSS Threading Tap

Price 1053 INR / Piece

Minimum Order Quantity : 1 Set

Shape : Straight Flute

Features : High Wear Resistance, Durable, Resharpenable

Operation Type : Other, Right Hand

Operate Method : Manual/Mechanical

STI Tap - Threading HSS

Price 353 INR

Minimum Order Quantity : 1 Set

Shape : Straight Flute

Features : High durability, rustresistant, precise threading, suitable for professional use

Operation Type : Other, Tapping

Operate Method : Hand or Machine Operated

Fluteless Threading Tap HSS

Price 1053 INR

Minimum Order Quantity : 1 Set

Shape : Cylindrical

Features : Chipless threading, high accuracy, durable, ideal for blind holes

Operation Type : Threading

Operate Method : Machine or hand operation

Reamer

Price 1053 INR

Minimum Order Quantity : 1 Piece

Shape : Straight Flute

Features : High precision, smooth finish, easy to operate

Operation Type : Other, Reaming

Operate Method : Manual

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry