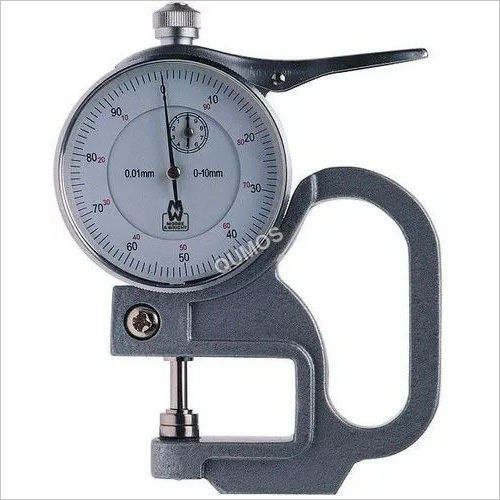

Dial Thickness Guage

Dial Thickness Guage Specification

- Cutting Force

- Manual Pressure

- Material

- Hardened Stainless Steel, Alloy Metal

- Length

- Approx. 120 mm

- Features

- Easy-to-read dial, Zero adjustment, Portable

- Hardness

- Body made from hardened steel

- Machine Type

- Hand Tool

- Coating

- No special coating

- Tool Type

- Thickness Guage

- Operation Type

- Manual

- Operate Method

- Manual, Lever Operated

- Shape

- Rectangular Body with C-Shaped Measuring Jaw

- Cutting Accuracy

- 0.01 mm (Dial Gauge Resolution)

- Diameter

- Measuring Jaw Diameter: Approx. 1015 mm

- Processing Type

- Measuring Instrument

- Dial Graduation

- 0.01 mm

- Color

- Blue Frame with White Dial

- Operating Temperature

- 5°C to 40°C

- Weight

- Approx. 200 g

- Measuring Faces

- Carbide-Tipped/Flat and Parallel Faces

- Usage

- Laboratory, Quality Control, Industrial, Educational

- Accuracy

- ±0.02 mm

- Application

- Paper, Sheet Metal, Film, Leather, Plastics, Textile Thickness Measurement

- Display Type

- Analog Dial

- Packaging Type

- Box

Dial Thickness Guage Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 1-7 Days

About Dial Thickness Guage

High Precision for Diverse Applications

Engineered for versatility, this dial thickness gauge is suitable for measuring a range of materials from delicate films to rigid sheet metals. The 0.01 mm dial graduation and 1015 mm jaw diameter cater to both fine and general thickness assessment, ensuring adaptability for laboratory analysis, industrial inspections, and quality assurance in the field.

Robust Engineering and User-Friendly Design

Manufactured from hardened stainless steel and alloy metals, and finished in a blue frame with a white dial, the tool promises durability with a professional appearance. Its zero adjustment feature, easy dial readability, and lever-operated manual pressure ensure effortless operation, making it suitable for both seasoned professionals and trainees.

FAQs of Dial Thickness Guage:

Q: How do I use the dial thickness gauge for accurate measurements?

A: To obtain accurate measurements, place your sample between the carbide-tipped, flat, and parallel faces of the measuring jaw. Apply gentle, manual lever pressure until the faces contact the material, ensuring even contact. Read the thickness value directly from the analog dial, which displays graduations of 0.01 mm.Q: What materials can this thickness gauge measure effectively?

A: This dial gauge is designed for a comprehensive range of materials, including paper, sheet metal, leather, plastic films, textiles, and other similar substrates. Its carbide-tipped measuring faces ensure reliable results across soft, flexible, and rigid materials.Q: Where is the best location or environment to operate this tool?

A: The gauge is suitable for a wide range of environments, such as laboratories, industrial quality control stations, educational settings, or any controlled workspace. For optimal performance, operate within the temperature range of 5C to 40C.Q: What is the benefit of the analog dial display and can the dial be adjusted to zero?

A: The analog dial is large and clear, providing immediate readings without the need for electronic power, ideal for quick reference. The tool also allows for zero-point adjustment, ensuring ongoing accuracy before each use.Q: How does the manual operation of this thickness gauge work?

A: Operation is manual and lever-based. The user applies moderate hand pressure on the lever to close the measuring jaws around the material, making it simple, efficient, and requiring no external power or batteries.Q: What sets this thickness gauge apart in terms of durability and construction?

A: The body is crafted from hardened stainless steel and alloy metal, providing high resistance to wear and ensuring longevity. Carbide-tipped faces enhance measuring consistency and maintain accuracy over time, even with frequent industrial or educational use.Q: When should this gauge be used for measurement processes?

A: This gauge is ideal whenever precise thickness measurements are required, such as before quality control checks, during production, or for educational demonstrations in material science. Use it as part of standard measurement procedures to validate material specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Precision Measuring Instruments Category

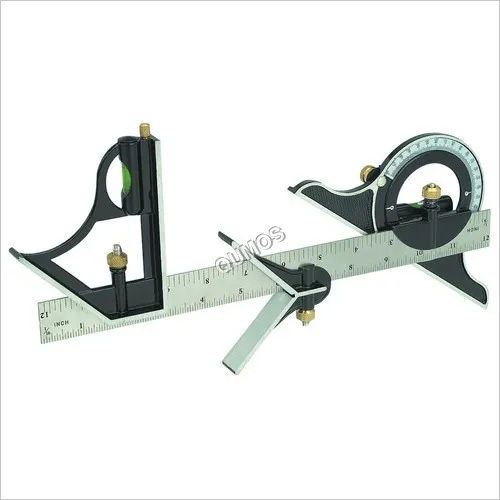

Combination Set

Price 1053 INR

Minimum Order Quantity : 1 Set

Features : Multifunctional tool with measurement leveling and angle finding capabilities

Material : Stainless steel and cast iron, Others

Tool Type : Combination set

Operate Method : Manual operation

Height Guage

Price 5300 INR

Minimum Order Quantity : 1 Set

Features : Corrosion resistant, Fine graduation, Rigid construction, Clear markings

Material : Stainless Steel

Tool Type : Measuring Tool

Operate Method : Manual

Micrometer Screw Guage

Price 1053 INR

Minimum Order Quantity : 1 Piece

Features : Compact Durable Multiple Models Available (EX1600 EX1602 EX1603 EX1604 EX1610)

Material : Metal

Tool Type : Micrometer Screw Gauge

Operate Method : Manual operation

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry