Carbide Tip

Carbide Tip Specification

- Cutting Capacity

- Suitable for steel, cast iron, non-ferrous metals

- Material

- Tungsten Carbide

- Length

- 50 mm to 150 mm

- Hardness

- High

- Cutting Force

- Low to medium

- Operation Type

- Cutting, Drilling

- Brooches Type

- Rotary Broaches

- Machine Type

- CNC, Lathe, Milling Machine

- Tool Type

- Carbide Tip

- Cutting Accuracy

- 0.01 mm

- Cutter Type

- Solid Carbide Cutters

- Cutting Speed

- Variable, up to 90 m/min

- Drill Bits Types

- Twist Drill, Flat Drill

- Shape

- Round

- Operate Method

- Manual and Machine Operation

- Features

- High durability, wear resistance, heat resistance, precise cutting

- Coating

- Uncoated

- Diameter

- 8 mm to 32 mm

- Maximum Torque

- 280 Nm

- Processing Type

- Milling, Drilling, Turning

- Weight

- 20g to 120g (depending on size)

- Replacement

- Replaceable tip

- Tolerance

- h6

- Life Cycle

- Long tool life

- Shank Type

- Straight and Tapered

- Blade Size

- As per requirement

- Packaging

- Plastic Box / Bulk

- Surface Finish

- Polished

- Application

- Metal Cutting, Woodworking, Industrial Machining

- Temperature Resistance

- Up to 800°C

About Carbide Tip

Superior Performance and Durability

Engineered with high-grade tungsten carbide, this cutting tool delivers exceptional durability and wear resistance. Its polished surface and uncoated design offer smooth operations and enhanced cutting life. Thanks to its hardness and heat resistance, users benefit from reduced downtime and consistent precision during long machining cycles.

Versatility Across Industries

The Carbide Tips straight and tapered shank options, along with varied blade sizes and shapes, make it suitable for a wide range of operations including milling, drilling, and turning. Its compatibility with manual and machine operations, from traditional lathes to advanced CNC equipment, supports seamless integration into any production environment.

Reliable Precision and Safety

Designed with a tight tolerance (h6) and cutting accuracy of 0.01 mm, the tool ensures precise outcomes even during complex tasks. Its robust construction allows variable speeds up to 90 m/min and manages cutting forces efficiently, providing operators with safe and accurate results for every project.

FAQs of Carbide Tip:

Q: How is the Carbide Tip used in different cutting applications?

A: The Carbide Tip can be utilized in various applications such as metal cutting, woodworking, and industrial machining. Its compatibility with milling, drilling, and turning operations makes it versatile, whether on CNC machines, lathes, or milling machines. Selection of the appropriate diameter and shape allows customization for different jobs.Q: What materials does this Carbide Tip efficiently cut through?

A: Built from tungsten carbide and featuring a highly polished finish, this tool is highly effective for cutting steel, cast iron, and non-ferrous metals, offering low to medium cutting force and optimal performance in both roughing and finishing processes.Q: When should I replace the Carbide Tip during operation?

A: The Carbide Tip is designed for long tool life, but it should be replaced when you notice a reduction in cutting accuracy, visible wear, or decreased cutting efficiency. Since the tips are replaceable, its easy to swap them out to maintain optimal productivity without changing the entire tool.Q: Where can the Carbide Tip be installed and operated?

A: Compatible with a variety of machine typessuch as CNC, lathe, and milling machinesthe Carbide Tip can be used in industrial workshops, manufacturing facilities, woodworking shops, and more. Its adaptable design supports both manual and machine-aided operations.Q: What process ensures the accurate fit of Carbide Tips?

A: Each Carbide Tip is manufactured with an h6 tolerance and precise straight or tapered shank, ensuring snug and secure installation in standard tool holders. This tight fitting contributes to its high cutting accuracy and stable performance.Q: How does the Carbide Tip benefit industrial operations?

A: By providing high durability, exceptional wear and heat resistance, and the ability to achieve precise cuts at variable speeds, the Carbide Tip minimizes downtime and replacement costs. Users benefit from consistent results, a longer tool lifespan, and greater flexibility in a wide range of applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Cutting Tools Category

STI Tap - Threading HSS

Price 353 INR

Minimum Order Quantity : 1 Set

Material : Others, High Speed Steel (HSS)

Hardness : HRC 6065

Operate Method : Hand or Machine Operated

Cutting Force : Low to Medium

Carbide Reamer - Kyocera

Price 253 INR

Minimum Order Quantity : 1 Piece

Material : Others, Solid Carbide

Hardness : HRA 89~93

Operate Method : Manual & CNC Compatible

Cutting Force : Low

Corner Radius End Mill - Rounde Edge Endmill

Price 553 INR

Minimum Order Quantity : 1 Piece

Material : Others, Solid carbide

Hardness : High hardness carbide material

Operate Method : Automatic (CNC operation)

Cutting Force : Optimized for CNC machining

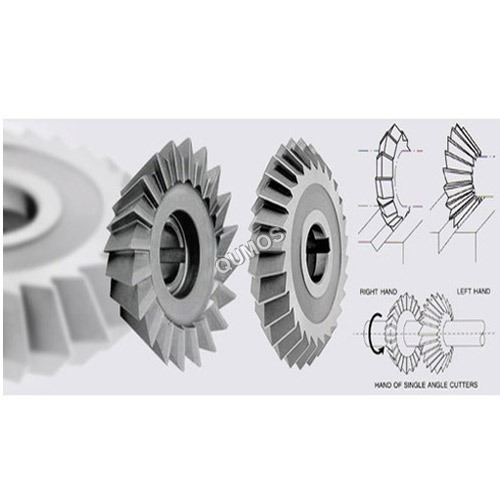

Angle Cutter HSS

Price 1053 INR

Minimum Order Quantity : 1 Piece

Material : Others, High Speed Steel (HSS)

Hardness : 5860 HRC

Operate Method : Manual or Machine Operated

Cutting Force : Optimized for efficiency

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry