Carbide Insert Threading Vardex Korloy Kyocera Taegutec Sandvik Widia Kennametal Ceratizit Walter

Carbide Insert Threading Vardex Korloy Kyocera Taegutec Sandvik Widia Kennametal Ceratizit Walter Specification

- Shape

- Triangle, Square, Round, Diamond

- Material

- Ultrafine grain carbide

- Cutting Speed

- Up to 350 m/min

- Length

- Insert lengths: 10-25 mm

- Coating

- CVD, PVD, TiN, TiAlN, TiCN

- Drill Bits Types

- N/A (application: threading inserts)

- Cutting Capacity

- Suitable for threading ranges M1-M150

- Operation Type

- Continuous/Intermittent

- Features

- High wear resistance, Precision threading, Optimized chip control

- Cutting Force

- Low to medium

- Cutting Accuracy

- 0.01 mm

- Cutter Type

- Internal and External threading

- Machine Type

- CNC Lathe, Turning Centers

- Hardness

- 92-94 HRA

- Operate Method

- Automated/CNC compatible

- Tool Type

- Threading Insert

- Coating Type

- Multi-layer PVD/CVD

- Diameter

- Insert sizes: 6 mm 30 mm

- Maximum Torque

- 80 Nm

- Processing Type

- Threading, Turning, Grooving

About Carbide Insert Threading Vardex Korloy Kyocera Taegutec Sandvik Widia Kennametal Ceratizit Walter

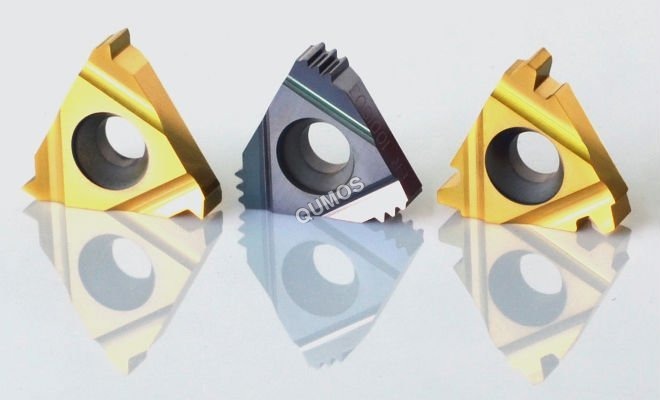

Carbide Insert Threading Vardex Korloy Kyocera Taegutec Sandvik Widia Kennametal Ceratizit Walter

We have a carbide grade to effectively thread almost any material. In addition to its general purpose grades, any threading insert can be coated in a specialty grade for the most demanding machining tasks. Our grade is the industry's best answer for machining stainless steel in high-production environments.

Carbide tips,carbide brazed inserts,carbide tipped inserts,carbide indexable tips,carbide saw tips,

Cutting, mining, saw tips, bars for crusher, dies, rods and other special carbide products. These products are mainly used in metal products industry, mining industry, machinery processing industries, etc.

boring tool, grooving tools and periphery turning tools. The inserts are sorted as clamped inserts, wood-cutting tools, milling & turning inserts, etc.

Many inserts for mining tools are made of tungsten carbide. Mining and tunneling cutting tools are fitted with Cemented Carbide tips so it is called "Button Bits". Only man-made diamond may replace the Cemented Carbide buttons when conditions are ideal, but as rock drilling is a tough task, Cemented Carbide button bits remain the most used type throughout the world.

Carbide inserts for metal cutting. Cemented carbide is easy to chipping and breaking. The carbide cutting tip is usually in the form of a small insert for a larger tipped tool whose shank is made of another material, usually carbon tool steel. Most modern face mills use carbide inserts, as well as many lathe tools and end mills and CNC.

Exceptional Threading Versatility

Suitable for a broad spectrum of thread profiles including ISO Metric, UN, BSPT, NPT, WT, and ACME, these carbide insert threading tools are compatible with most major brands. Their indexable and replaceable nature streamlines continuous or intermittent operations on CNC lathes and turning centers, enhancing efficiency across diverse industries.

Advanced Coating and Chip Control Technology

Insert coatings such as multi-layer CVD and PVD (TiN, TiAlN, TiCN) provide superior hardness (9294 HRA) and wear resistance, ensuring longer life cycles. Multiple chipbreaker geometries optimize chip control for smoother operations and consistent surface finishing down to Ra < 0.8 m.

Superior Performance in Demanding Applications

Designed for high-speed threading (up to 350 m/min) with precision (0.01 mm accuracy), these inserts operate reliably under high temperatures (up to 800C). Their ultrafine grain carbide structure supports low-to-medium cutting forces across threading ranges M1M150, ensuring high productivity and durability for automotive, aerospace, and oil & gas sectors.

FAQs of Carbide Insert Threading Vardex Korloy Kyocera Taegutec Sandvik Widia Kennametal Ceratizit Walter:

Q: How do I select the appropriate carbide threading insert for my application?

A: Choosing the right threading insert depends on your thread profile standard (ISO Metric, UN, BSPT, NPT, WT, ACME), required grade (e.g., VP15TF, PC9030, TT8115), and machining conditions. Refer to your machine compatibility, thread size, desired surface finish, and application industry to match the suitable brand and insert specification.Q: What are the main benefits of using multi-brand carbide threading inserts in CNC operations?

A: Using compatible carbide threading inserts across Vardex, Korloy, Kyocera, and others ensures flexibility in procurement, high cutting speeds, low cutting forces, and robust performance at elevated temperatures. Their advanced coatings and optimized chipbreaker design lead to extended tool life and precise threading with excellent surface quality.Q: When should I replace or index threading inserts during production?

A: You should replace or index threading inserts when you observe increased tool wear, reduced surface finish quality, or noticeable drops in threading precision. Replacing inserts from their box pack (10 per box) ensures continuous, uninterrupted machining and maintains high threading standards.Q: Where can these carbide threading inserts be used effectively?

A: These inserts are well-suited for automotive, aerospace, oil & gas, and general machining applications. They perform optimally on CNC lathes and turning centers for both internal and external threading, offering versatility across different thread profiles and material types.Q: What is the process for installing and using threading inserts on CNC machinery?

A: Installation involves inserting the carbide threading tool into the compatible CNC lathe or turning center holder, securing it to manufacturer-recommended torque settings (up to 80 Nm). Select the correct insert geometry, size, and coating for your threading operation, then set up cooling (through-coolant models when required) and begin the machining cycle.Q: How do these inserts enhance threading accuracy and lifespan in manufacturing?

A: Precision engineering (0.01 mm accuracy), advanced coatings, and optimized chip control mechanisms ensure minimal wear, improved threading accuracy, and extended life cycles, even during high-speed or high-temperature operations. The indexable, replaceable design allows for consistent performance and cost-effective tool management.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Engineering Cutting Tools Category

Counter Sink

Price 786 INR

Minimum Order Quantity : 1 Piece

Features : Durable precision cutting wearresistant coating

Material : Others, Highspeed steel (HSS) or carbide

Hardness : High (toolgrade material)

Tool Type : Drill cutting tool

Solid Carbide Drill Bit

Price 1053 INR

Minimum Order Quantity : 1 Piece

Features : High Wear Resistance, Long Tool Life, Precision Drilling, AntiCorrosive

Material : Others, Solid Carbide

Hardness : 92 HRC

Tool Type : Drill Bit

Interrupted Thread Tap

Price 1521 INR

Minimum Order Quantity : 1 Set

Features : Reduced chip buildup suitable for threading operations with interrupted areas

Material : Others, HighSpeed Steel (HSS)

Hardness : High

Tool Type : Cutting Tool

Straight Flute Tap - HSS Threading

Price 753 INR

Minimum Order Quantity : 1 Set

Features : Straight flute design suitable for threading

Material : HighSpeed Steel (HSS), Others

Hardness : HighSpeed Steel (HSS)

Tool Type : Straight Flute Tap

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry